- Department of Surgery, College of Medicine, University of Baghdad, Baghdad, Iraq

- Department of Biomedical Engineering, Al-Nahrain University, Baghdad, Iraq

- Department of Surgery, Baghdad Teaching Hospital Baghdad, Baghdad, Iraq

Correspondence Address:

Moneer K. Faraj, Department of Surgery, College of Medicine, University of Baghdad, Baghdad, Iraq.

DOI:10.25259/SNI_505_2024

Copyright: © 2024 Surgical Neurology International This is an open-access article distributed under the terms of the Creative Commons Attribution-Non Commercial-Share Alike 4.0 License, which allows others to remix, transform, and build upon the work non-commercially, as long as the author is credited and the new creations are licensed under the identical terms.How to cite this article: Moneer K. Faraj1, Rana I. Abed2, Sadiq Jafer Hamandi2, Mustafa Ismail3. Innovative surgical precision: The electronic pen needle holder based on neurophysiological principles. 26-Jul-2024;15:264

How to cite this URL: Moneer K. Faraj1, Rana I. Abed2, Sadiq Jafer Hamandi2, Mustafa Ismail3. Innovative surgical precision: The electronic pen needle holder based on neurophysiological principles. 26-Jul-2024;15:264. Available from: https://surgicalneurologyint.com/surgicalint-articles/13006/

Abstract

Background: The electronic pen needle holder (EPNH) was developed to enhance surgical precision, reduce operative time, and improve patient outcomes. By integrating microergonomics, penization, and electronics with surgical instruments, the EPNH aims to provide surgeons with a tool that minimizes hand strain and maximizes control during delicate procedures.

Methods: The EPNH was ergonomically designed to fit the surgeon’s hand, using titanium for its strength and biocompatibility. It was manufactured through industrial-grade 3D printing, and its mechanical properties were verified using finite element analysis. A force-sensitive resistor and vibratory mechanism were integrated to provide real-time feedback and assistance during surgeries.

Results: Testing by 10 neurosurgeons demonstrated significant precision, control, and efficiency improvements. The EPNH reduced hand strain and fatigue, allowing longer, more comfortable operation times. The time required for suturing tasks has decreased by 40% compared to traditional needle holders. Surgeons reported high satisfaction with the EPNH’s performance and usability.

Conclusion: The EPNH represents a major advancement in surgical instrument design, offering enhanced precision, reduced hand strain, and increased efficiency. Its innovative features and ergonomic design make it a valuable tool for improving surgical outcomes and transforming microsurgical practices.

Keywords: Electronics integrated with surgical instruments, Ergonomics, Microsurgery, Needle holder, Precision

INTRODUCTION

Surgical instruments have always been evolving to meet the three most important requirements of surgery – preciseness of the operation, reduction of operative time, and improvement in the patient’s outcome. Conventionally, the design of surgical instruments has been targeted toward the tissue that is the focus of interest, with little attention to ergonomics as far as the surgeon’s hand is concerned. However, with the advent of microergonomics – sub-branching from the field of ergonomics, which places a central focus on the design of hand tools to suit the intricate movements and functionalities of the human hand – this reality may soon change. Microergonomics aims to reduce surgeon fatigue while increasing precision, efficiency, and overall surgery safety.

This is one of the groundbreaking innovations, reflecting the application of microergonomics rules, such as an electronic pen needle holder (EPNH). One of this paper’s authors proposed electronics integrated with surgical instruments (EISI) for the 1st time. The EISI is to equip some classical surgical instruments with electronic chips to assist and make it easy for surgeons to do their jobs during operations. Other definitions, like penization, have been used to rediscover mechanisms into pen-like mechanisms, giving 360° control by the surgeon’s hand. This will result in a so-called pen needle holder. Combining both should make it possible to pass needles with a view to hard tissues. This is still quite a problem with delicate microsurgical work, although it is used in neurosurgery.[

The paper’s key objective is to consider, from a microergonomic perspective, the design and development of the EPNH. We will discuss how the principles of penization – modifying surgical instruments to resemble the familiar and highly controllable shape of a pen – are applied to create a device that significantly reduces hand tremors and increases precision. In addition, we will examine the incorporation of EISI to further assist surgeons in performing delicate procedures with minimal effort.[

This paper tries to establish how the EPNH, based on microergonomic principles, provides an essential breakthrough in surgical tool design. This novel device is going to revolutionize surgical practices and bring betterment for surgeons as well as patients. The incorporation of EISI and penization increases not only the usability of the instrument but also decreases, to a significant extent, surgeon fatigue, improving the precision and control during operations, hence making it a very resourceful tool in microsurgery.[

MATERIALS AND METHODS

Design and development of the EPNH

In this EPNH, the principles of microergonomics, penization, and EISI are designed and developed. It aims to provide the surgeon with a surgical tool of the utmost precision, minimize fatigue, and facilitate easy passage of needles through tough tissues during delicate microsurgical procedures that it is called on to perform.

Conceptual framework

The EPNH was designed to fit the anatomy of the surgeon’s hand, reducing strain while maximizing control; this is a cardinal factor of microergonomics. Decimalization into the shape of this pen-like instrument brought about finer use and ease, sometimes called penization. Increasing electronic components also gives this instrument real-time feedback and assistance.

Material selection and 3D printing

Titanium was used because it has high tensile strength, is biocompatible, and is corrosion resistant. The design model was prepared using SOLIDWORKS 2022 software, and printing was done on a Riton – Industrial-grade metal 3D printer (TI-150). The printing process involves dust-free surroundings, uniformly spreading titanium powder material on the base plate, and printing the model layer by layer; it takes about 32 hours. Post-processing involved cleaning and preparing the printed components, which had to be welded or fitted together as small internal components. The final design of the EPNH is shown in

Finite element analysis

The mechanical properties of EPNH have been estimated using ANSYS Workbench 2022 R1. A mesh size of 1 mm was used to obtain proper simulation results in the model. Forces were applied to simulate real-life usage, including reaction forces on the jaws and the force exerted by the surgeon’s thumb. The simulation calculated the safety factor, equivalent stress, strain, and total deformation to ensure the device’s mechanical safety. The maximum stress observed was 176.91 MPa, well within the material’s yield strength.

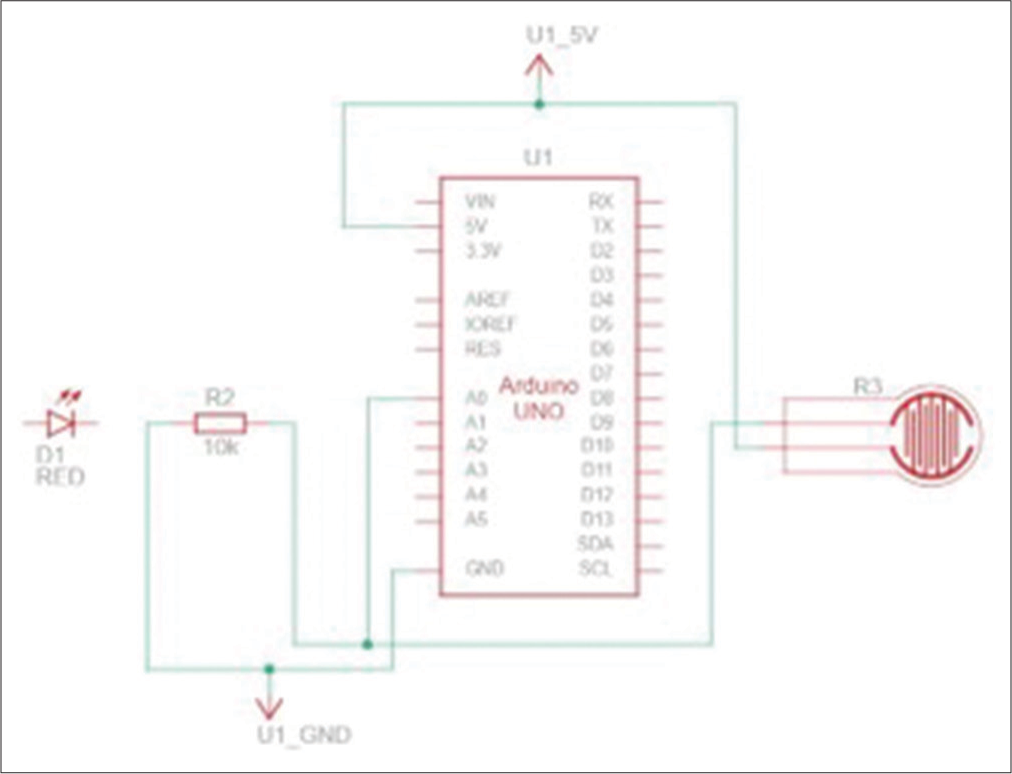

Electronics integration

An electronic hybrid circuit was designed and added to the EPNH to enhance its capability. A force-sensitive resistor fitted at the tip of the index finger measured the pressure the surgeon’s thumb applied. Suppose the pressure crosses the threshold of 8N. In that case, it triggers some unidirectional vibrators embedded in the needle holder that create a hammer effect, helping the needle pierce more inflexible tissues. These electronics were programmed using Arduino software to work precisely and are responsive.

Evaluation in the practice

The tool was tested on ten neurosurgeons performing microsurgical procedures using a traditional needle holder compared to a new electronic one. Each surgeon’s performance was video recorded and analyzed in terms of precision, strain, time taken to finish, and hand fatigue while suturing tasks. Feedback was collected through a special questionnaire rating traditional and electronic needle holders. This work demonstrated a significant reduction in operative time and surgeon fatigue with a marked improvement in precision.

RESULTS

Practical evaluation

The EPNH was assessed through practical testing by ten neurosurgeons performing several microsurgical procedures. This research instrument highlighted precision, strain, fatigue in the hand, and time efficiency compared with traditional holding techniques for needles.

Precision and control

EPNH had better control and precision; it showed at times of delicate suturing. The pen-like design made it very easy for surgeons to maneuver the instrument, reducing hand tremors to a large extent. With the inclusion of electronic components, there was much enhanced control while working with tough tissues.

Reduction in hand strain and fatigue

The surgeons reported less strain on their hands and decreased fatigue when performing tasks using the EPNH. Thus, physical effort was reduced by the ergonomic design; it extended the periods possible to operate without discomfort. Feedback from the FRS and the vibratory mechanism was vital in this aspect.

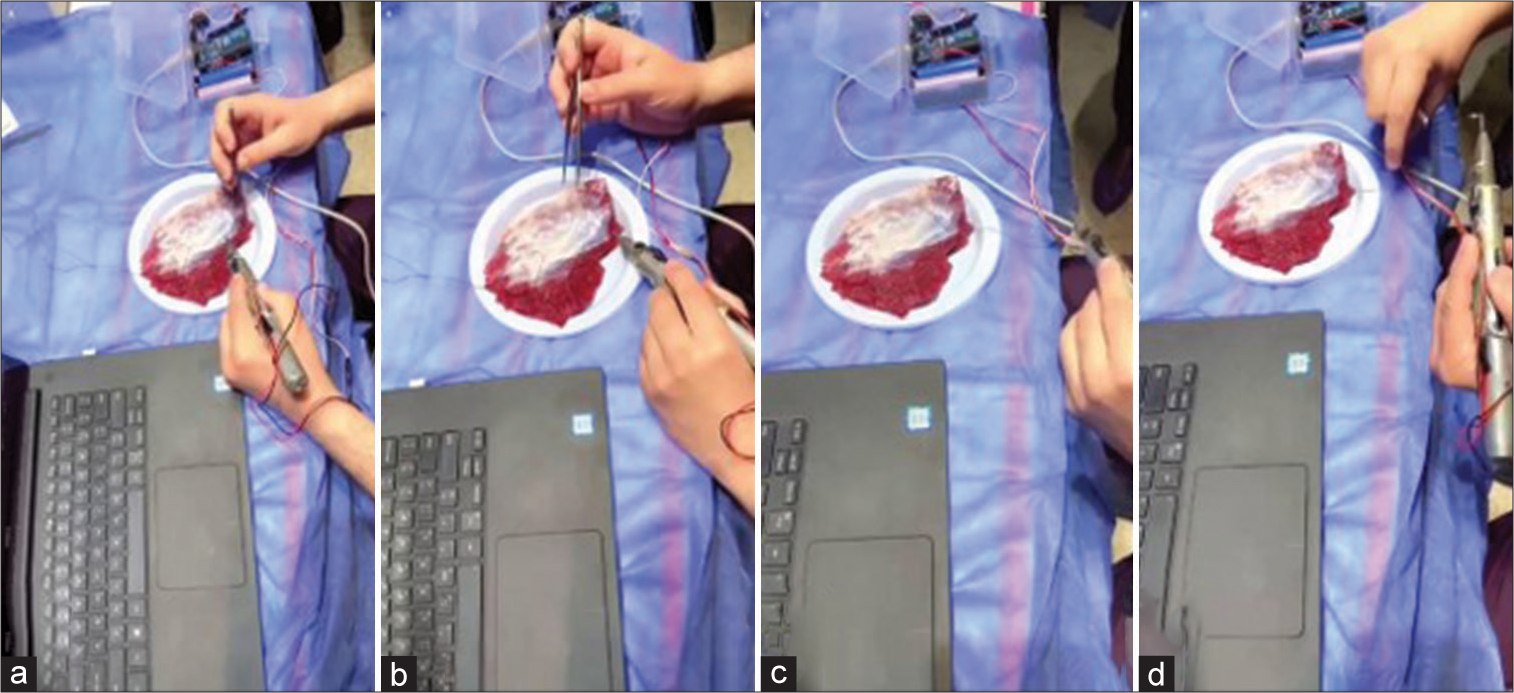

Figure 3:

(a) The surgeon uses the electronic pen needle holder (EPNH) to initiate a precise suturing task, demonstrating the ergonomic grip and microergonomic design. (b) The EPNH, in action, showcases the integration of force-sensitive resistor technology, providing real-time feedback for improved control during the procedure. (c) Continued use of the EPNH, highlighting the reduced hand strain and increased precision due to the penization concept. (d) The surgeon completed the suturing task with the EPNH, demonstrating enhanced efficiency and reduced operative time, as supported by the study results.

Efficiency and time savings

The time taken to operate on patients was significantly reduced with the introduction of EPNH. An electronic vibratory mechanism facilitating the ease of passing through tough tissues made it easier for surgeons to conduct suturing tasks. The average reduction in the time taken to complete the suturing tasks was reduced by about 40% compared to traditional needle holders.

Feedback and questionnaire results

Feedback questionnaires among the surgeons revealed high satisfaction. They identified improved precision, reduced fatigue, and increased efficiency as significant advantages of the EPNH.

Neurophysiological principles

The construction and principles of operation of the EPNH are based at the level of neurophysiology with an emphasis on augmenting innate hand control mechanisms. Engineered to work within the densely layered neurophysiological mechanisms of hand movement and sensory feedback, whenever possible, the EPNH dampens hand tremors while maintaining precision. Integration of a FSR coupled with a vibratory motor mechanism enables real-time feedback, which is synchronized with neurophysiology to enable fine motor control and tactile sensory experience. This pioneering approach supports the EPNH to be comfortably fitted into the surgeon’s hand and provides an additional benefit for performing fine motor tasks even more precisely and fatigue free. This neurophysiological congruence opens a new era of surgical transformation and constitutes an important leap in neurosurgery.

DISCUSSION

Therefore, The EPNH is a marvelous innovation in the design of surgical instruments and more so in microsurgery, for it combines principles in microergonomics, penization, and EISI to solve some significant problems surgeons face with precision, hand strain, and efficiency.

Enhanced precision and control

Other vital benefits of EPNH are increased precision and control, which are essential in microsurgical operations. The pen-shaped design of the device, as a simple application of the theory of penization, will ensure that surgeons can manipulate the device using hand movements similar to holding a pen. It causes minimal handshaking and enhances accuracy in very accurate work. The ESR and vibratory mechanism further enhance control when dissecting through dense tissues.[

Reduction in hand strain and fatigue

Surgeon fatigue is a well-documented issue that can impact performance and patient outcomes. The ergonomic design of the EPNH minimizes physical effort and reduces hand strain, allowing surgeons to operate for longer periods without discomfort. This reduction in fatigue is crucial for maintaining high levels of precision throughout lengthy procedures.[

Increased efficiency and time savings

Practical evaluation tests unequivocally demonstrated that EPNH substantially curtailed operative duration. Most of the abbreviation in the time taken for operation underneath this apparatus is ascribed to the simplicity wherewith it permitted the transit of needles through obstinate tissues compared to traditional needle-holders. The oscillatory system facilitates this transit, bettering the procedure’s velocity. Contrasted with conventional needle holders, it decreased an average of about 40% of the time to consummate each suturing job. Such savings in time would yield in proficient surgical workflows and diminished operating room costs.[

Positive feedback from surgeons

The feedback from surgeons after trying EPNH tests was auspicious. Appreciation was shown for improvements in precision, fewer feelings of fatigue, and increased efficiency. This positive reception suggests that the EPNH could be widely adopted in surgical practice, leading to better outcomes for surgeons and patients.[

Future directions and improvements

While a considerate EPNH design already exists that reflects several benefits, further innovations can still be made in this regard. Advanced electronic features, including tissue differentiation sensors and methods for giving real-time feedback, could form part of future tool versions. In addition, further refinement of the ergonomic design could enhance comfort and usability even more. Collaboration between surgical instrument manufacturers and technology companies could drive these advancements, leading to more effective surgical tools.

CONCLUSION

The EPNH is a breakthrough in surgical instrument design and, more so, in microsurgery. This lets the EPNH consolidate features of macroeconomics and penalization principles with some state-of-the-art electronic features to offer improved performance for such definite challenges in precision, strain on the hand, and efficiency. A pen-like grip provides better handling and control, while the FSR and vibratory mechanism improve performance in harsh tissue conditions. Practical tests revealed that the EPNH could significantly reduce hand strain and operative times, a good reception from surgeons that underlined improved precision and operative efficiency. With its improved design functionality, the EPNH will raise a new bar of standards for surgical tools and foster improved results on both the surgeon and patient sides. Transforming surgical practices concerning precision, physical strain, and procedural efficiency can offer much more than existing solutions.

Ethical approval

The Institutional Review Board approval is not required.

Declaration of patient consent

Patient’s consent was not required as there are no patients in this study.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

Use of artificial intelligence (AI)-assisted technology for manuscript preparation

The authors confirm that there was no use of artificial intelligence (AI)-assisted technology for assisting in the writing or editing of the manuscript and no images were manipulated using AI.

Disclaimer

The views and opinions expressed in this article are those of the authors and do not necessarily reflect the official policy or position of the Journal or its management. The information contained in this article should not be considered to be medical advice; patients should consult their own physicians for advice as to their specific medical needs.

References

1. Faraj MK. What are “microergonomics” “penization” and “electronics integrated with surgical instruments”?. World Neurosurg. 2021. 152: 144-51

2. Papaspyros SC, Kar A, O’Regan D. Surgical ergonomics. Analysis of technical skills, simulation models, and assessment methods. Int J Surg. 2015. 18: 83-7

3. Seagull FJ. Disparities between industrial and surgical ergonomics. Work. 2012. 41: 4669-72

4. Shimizu S, Kuroda H, Mochizuki T, Kumabe T. Ergonomics-based positioning of the operating handle of surgical microscopes. Neurol Med Chir. 2020. 60: 313-6

5. Stucky CC, Cromwell KD, Voss RK, Chiang YJ, Woodman K, Lee JE. Surgeon symptoms, strain, and selections: Systematic review and meta-analysis of surgical ergonomics. Ann Med Surg (Lond). 2018. 27: 1-8