- Department of Surgery, College of Medicine, University of Baghdad, Baghdad, Iraq

- Department of Biomedical Engineering, Al-Nahrain University, Baghdad, Iraq

- Department of Neurosurgery, Neurosurgery Teaching Hospital, Baghdad, Iraq

Correspondence Address:

Moneer K. Faraj, Department of Surgery, College of Medicine, University of Baghdad, Baghdad, Iraq.

DOI:10.25259/SNI_861_2024

Copyright: © 2024 Surgical Neurology International This is an open-access article distributed under the terms of the Creative Commons Attribution-Non Commercial-Share Alike 4.0 License, which allows others to remix, transform, and build upon the work non-commercially, as long as the author is credited and the new creations are licensed under the identical terms.How to cite this article: Moneer K. Faraj1, Auns Q. H. Al-Neami2, Ibraheem Forat Hussein2, Mustafa Ismail3. The flute: A new microsurgical instrument performing the work of three instruments simultaneously. 08-Nov-2024;15:410

How to cite this URL: Moneer K. Faraj1, Auns Q. H. Al-Neami2, Ibraheem Forat Hussein2, Mustafa Ismail3. The flute: A new microsurgical instrument performing the work of three instruments simultaneously. 08-Nov-2024;15:410. Available from: https://surgicalneurologyint.com/surgicalint-articles/13204/

Abstract

Background: The surgical suction, irrigator, and retractor are vital instruments in all operative neurosurgical interventions. Several trials previously tried to combine these instruments to reduce the number of working hands in the surgical field and make them more controllable by the surgeon. An instrument combined the suction and irrigation used, and others added suction with the dissector, which was also invented but with many drawbacks.

Methods: We designed a new surgical instrument that performs the function of three surgical instruments simultaneously. It works as a dissector, suction, and irrigator in the surgical field. Its innovative design unites three instruments, and every one of them has its holding method by the surgeon’s hand. They united into one maneuver. The surgeon’s work becomes easier by decreasing the number of hands in the surgical field; this will result in a reduction in time and better efficiency. Furthermore, its innovative design reduces the possibility of blockage of the suction tube, and the feasibility of reopening is much easier as compared with the available suction.

Results: We use the 3D-printed design of the instrument by neurosurgeons. It was quite comfortable with better control by the surgeon and reduced the number of hands in the field, resulting in an increment of the operative field visible to the surgeon.

Conclusion: This new instrument acts as three conventional instruments simultaneously to provide better control to the surgeon and increase the operative field visible to the surgeon.

Keywords: 3D-printed designs, New instruments, Surgical instruments

INTRODUCTION

In the realm of microsurgery, the precision and efficacy of the instruments used are critical to achieve successful surgical outcomes. The suction tube, irrigator, and dissector are indispensable tools for ensuring a clean, controlled surgical field and allowing the surgeon to perform the intricate maneuvers required during delicate procedures. Recognizing the need for more efficient surgical instruments, multiple attempts have been made to consolidate the roles of these tools into a single, multifunctional device. These innovations aimed to minimize the number of instruments required during surgery, potentially decreasing the number of surgical assistants needed and reducing the complexity of hand movements within the confined operative space.

An early invention combined the functions of suction and irrigation into a single metal tube linked to two plastic tubes – one connected to a suction device and the other to a saline perfusion system. However, this device could not carry out both functions at the same time because it needed to act alternately between suction and irrigation, which seriously impeded its practical use efficiency.[

Later on, a more evolved system was built, which had two metal tubes that were attached to both suction and irrigation apparatuses. This design enabled the simultaneous working of the two mechanisms; hence, it was more practically useful during surgery, and it facilitated ease in workflow.[

A more recent development yielded an instrument with a hollow, open terminal end through which blood and fluids could be aspirated simultaneously while dissecting tissue. This tool had, unfortunately, two major disadvantages: the suction port would often be occluded by the dissected tissue, and if adjusted, the suction would interfere with the surgeon’s line of sight by removing the fluid from the same space being observed[

Figure 3:

This dissector has an open end with a hollow connected to a suction device, but the drawback of this tool is that the hollow is at the end of the surgeon’s working area. When using the dissector, the opening tip will be closed by the tissues, preventing it from suctioning, and if the hollow rotates to the other side, the aspirated fluid will cover the field that the surgeon works in.

The ongoing challenge in microsurgery is to improve the ergonomics and functionality of surgical tools while reducing the number needed to obtain a high level of precision. This study describes the design and capability of a new microsurgical instrument that combines three tasks – suction, irrigation, and dissection – into one comprehensive instrument. This novel tool tries to address some deficiencies of the previous designs by optimizing the surgical motions of the hands in such a way that it will advance the surgeon’s control, improve patient outcomes, and decrease operative time. The design of this instrument, its advantages over available tools, and its possible implications concerning microsurgical approaches are discussed.

MATERIALS AND METHODS

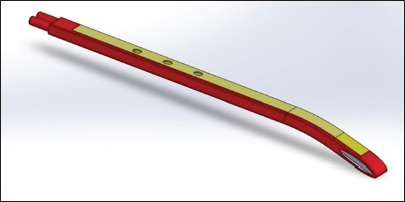

A novel surgical instrument was designed to perform the functions of three separate tools –suction, irrigation, and dissection – simultaneously [

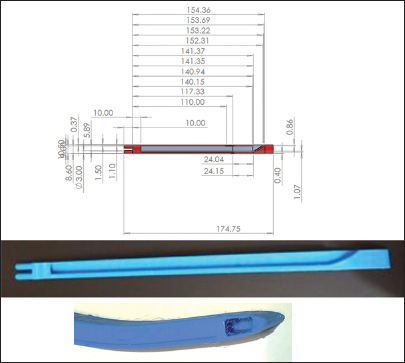

The lower piece of the instrument is 174.75 mm in length, tapering from a width of 3.2 mm at the top to 2.70 mm at the bottom. At the head of this component, two tubes are designed to connect both the irrigation and suction plastic tubes [

The suction tube is connected through a broad groove that runs the length of the lower piece. This groove is specifically designed to minimize the risk of blockage by blood or other secretions. The suction port is positioned on the left side of the irrigation hole, and its length is 10.94 mm [

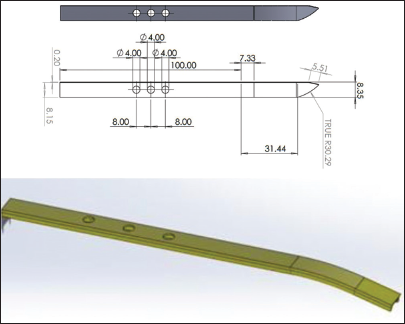

The upper piece of the instrument is equipped with three holes and functions as a control mechanism for the suction system. By pressing these holes, the surgeon can regulate the pressure and, consequently, the amount of fluid withdrawn from the surgical field. This upper component is designed to fit seamlessly with the lower piece and can be easily detached for cleaning and sterilization [

This is a multifunctional instrument to be used with one hand, freeing the surgeon to control fluid suction, tissue dissection, and irrigation simultaneously [

RESULTS

A three-dimensional model of a newly designed instrument made from polylactic acid (PLA) material is strong and durable, being a common thermoplastic used in prototyping. After printing, the model was tested for its ability to perform all three critical functions of microsurgery-tissue manipulation or dissection, irrigation, and fluid suction simultaneously. These functions were observed under controlled conditions and proved that this instrument is capable of executing the said job properly and effectively.

The prototype proved quite versatile, either for one-time uses in applications needing it to be used once and then sterilized or, in the case of manufacture out of stainless steel, reuse over a very long period. A version done in stainless steel, therefore would be particularly useful with reuse many times since it is strong and maintained sterile through different types of surgeries.

It successfully undertakes the work of three separate surgical tools: suction, irrigation, and dissection. Its application minimizes assisting hands in the surgical field and thus provides unobstructed visibility to the surgeon for greater precision in the procedure. The smaller number of hands in the operating area minimizes contamination and enhances the overall ergonomic efficiency of the surgical team.

In this respect, the instrument has quite interesting economic potential. Replacing three unique instruments with one polyfunctional device allows hospitals and surgical centers to save expenses in the purchase of various spare instruments and their processing. Furthermore, the design provides for reducing the risk of suction tube blockage, one of the usual problems with earlier instruments. The wide grove for suction gives way to a more regular flow, reducing the interruptions caused by blood or tissue clogging; it enhances efficiency in withdrawal and heightens the whole workflow of fluid surgery.

This novel instrument, therefore, is significant not only because it economizes the time used in the operation by putting together two necessary functions involved but also has the potential to improve surgical outcomes by imparting greater control to the surgeon and reducing costs on account of maintaining and replacing instruments.

DISCUSSION

Novel surgical tool development, in general, and for neurosurgery, in particular, remains a major driving force for the advancement of precision, speed, and operative outcomes. Advanced technologies, such as multifunctional surgical instrument development, are making surgical procedures easier by giving more control to surgeons while minimizing the need for several assistants in the operating field.[

Our findings showed that this newly designed microsurgical instrument has great potential in terms of improving the efficiency and ergonomics of surgical procedures. The prototype, three-dimensionally printed from PLA, combined the functions of suction, irrigation, and tissue dissection in a single device. Consequently, this multifunctional instrument also reduced the complexity of hand maneuvers within the surgical field while it was performing these tasks simultaneously and became a significant development in microsurgical tool design. The improved visibility and control of the surgeon during this study have, therefore yielded one very important outcome, which is that. By bringing together three simple functions in one tool, the number of hands in the operative field was minimal, while the wide surgeon’s visual field increased simultaneously. Both factors are the most important for more precise surgical movement and a neat working area, which would become highly important in sensitive microsurgical procedures. This fact is exceptionally useful for keeping the surgical field clear and dry by the ability to perform suction and irrigation together, not having to change manually between the tools.

Another important advantage of the instrument in question proceeds from its ergonomic design. The hand movements become less because the device can control fluid management and tissue dissection with one hand. This would likely help decrease fatigue over prolonged procedures and, in effect, improve the performance of surgeons and patient outcomes. The instrument also minimizes the amount of contamination in the surgical field by reducing assistant hands.

Our tests also confirmed the strength of the instrument design concerning blockage prevention, which is a very common problem with conventional suction devices. The broader groove used for suction, coupled with the surface tension of the water, maintained consistent fluid withdrawal that prevented obstructions from blood or tissue fragments. This feature is particularly important in maintaining uninterruptible suction, increasing workflow efficiency during surgery.

Innovation in neurosurgery has helped balance cost-effectiveness while improving patient outcomes. Since it would appear that costs in the area of health care continue to rise across the globe, it is important to initiate innovations that could enhance quality while decreasing expenses. Certain surgical advances can help reduce hospital stays, reduce infection rates, or consolidate multiple tool use into a single device; each will be associated with significant cost savings. Of course, there needs to be continuous economic evaluation of these innovations to ensure that the innovations are clinically and financially beneficial.[

Barkley[

The ethical dimensions of surgical innovation are of crucial importance – in ways both overt and subtle – to the assurance of patient safety and retention of trust in the profession. New procedures carry new hazards, and their development must be necessarily cautious and monitored. The ethical considerations require that a novel surgical procedure undergoes review by Institutional Review Boards to reduce the risk to patients and ensure truly informed consent. The pace of innovation must be balanced against the imperative of patient safety, where even well-meaning experimentation should be constrained by ethical guidelines that protect patients while continuing to advance surgical practices.[

More briefly, our results point out that this novel tool works and may become useful for easing surgical work processes, enhancing precision, and, in the future, reducing costs. This new design overcomes the typical working limitations, such as blockages or the need for multiple assistants that characterize most of the existing tools, offering an easier approach toward the microsurgery area. Long-term efficiency and clinical effectiveness will need to be proven in further studies concerning patient outcomes.

CONCLUSION

The development of this new microsurgical instrument is a huge step toward the betterment of surgical effectiveness, precision control, and human factor engineering. Lessons learned from making all three functions – suction, irrigation, and dissection – in one device may facilitate many procedures, give surgeons greater precision, and minimize assistants in the operating field. These translate into improved visibility, workflow, and reduction of manual handling, culminating in better surgical outcomes with concurrent economic advantages through cost reduction and flexible usability. Its complete potential could be further realized in future studies done in a clinical setting involving a wide range of surgical specialties. Indeed, much work may be needed for further research regarding long-term outcomes, patient safety, and comparative effectiveness against traditional tools.

Ethical approval

Institutional Review Board approval is not required.

Declaration of patient consent

Patient’s consent is not required as there are no patients in this study.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

Use of artificial intelligence (AI)-assisted technology for manuscript preparation

The authors confirm that there was no use of artificial intelligence (AI)-assisted technology for assisting in the writing or editing of the manuscript and no images were manipulated using AI.

Disclaimer

The views and opinions expressed in this article are those of the authors and do not necessarily reflect the official policy or position of the Journal or its management. The information contained in this article should not be considered to be medical advice; patients should consult their own physicians for advice as to their specific medical needs.

References

1. Barkley A. The interface of global neurosurgery and technological innovation: A vision for the future. J Global Neurosurg. 2023. 3: 1

2. Bernstein M, Bampoe J. Surgical innovation or surgical evolution: An ethical and practical guide to handling novel neurosurgical procedures. J Neurosurg. 2004. 100: 2-7

3. Dabadi S, Dhungel RR, Acharya S, Acharya S, Shrestha J, Dhakal S. Engineering and innovations in neurosurgery. Annapurna J Health Sci. 2022. 2: 51-8

4. Fransson BA, Mayhew PD, editors. Small animal laparoscopy and thoracoscopy. Maryland: American College of Veterinary Surgeons Foundation; 2021. p. 375

5. Lo PC, Kung WM. Innovation, advances, and updates in neurosurgery. Signa Vitae. 2022. 18: 1-7

6. Ma K. Minimal access gardening: Laparoscopic techniques during coronavirus disease lockdown. J Minim Invasive Gynecol. 2021. 28: 22-3

7. Oertel J, Gen M, Krauss JK, Zumkeller M, Gaab MR. The use of waterjet dissection in endoscopic neurosurgery. Technical note. J Neurosurg. 2006. 105: 928-31

8. Wallwiener D, Stumpf B, Bastert G, Mueller W. Multifunctional instrument for operative laparoscopy: Technical, experimental, and clinical results in gynecology. Endosc Surg Allied Technol. 1995. 3: 119-24

9. White EJ, McMahon M, Walsh MT, Coffey JC, O’Sullivan LW. A study of laparoscopic instrument use during colorectal surgery. Appl Ergon. 2019. 78: 301-8

10. Witiw CD, Nathan V, Bernstein M. Economics, innovation, and quality improvement in neurosurgery. Neurosurg Clin. 2015. 26: 197-205 viii